Improving the fatigue life of additive manufacturing components

Additive manufacturing enables engineers to create complex geometric shapes that were once prohibitively expensive or even impossible to manufacture using traditional manufacturing methods.

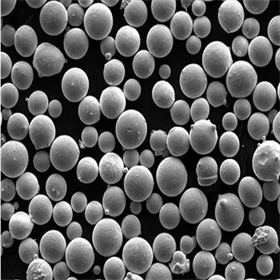

The advancement of powder metallurgy for additive manufacturing (AM) raw materials has provided a wide range of choices for high-temperature alloy powders. Due to the difficulties in processing nickel-based high-temperature alloys using traditional methods, additive manufacturing using nickel-based high-temperature alloys is rapidly becoming popular. For example, AM Inconel 718 is a high-strength nickel-based, high-temperature alloy commonly encountered in jet engines and gas turbines.

Despite the continuous improvement of additive manufacturing technology, parts are usually not used for fatigue-critical applications. Compared with traditional manufactured components, surface reinforcement processes with compressive residual stress have significant improvements.

A research team has concluded through testing the surface treatment additive manufacturing Inconel 718 that applying compressive residual stress can significantly prolong fatigue life, even approaching the fatigue life of traditional forging materials. Residual compression may allow for considering additive manufacturing components for fatigue-critical applications. By adding mechanical surface reinforcement and engineering compressive residual stress during the manufacturing process of additive manufacturing parts, acceptable levels of fatigue performance can be achieved.

Trunnano 3D Printing Nickel Alloy IN718 Powder

Inconel 718 is a particularly excellent nickel-based high-temperature alloy extensively used in many fields due to its high-temperature strength, strong oxidation resistance, and good corrosion resistance. In the field of additive manufacturing, Inconel 718 alloy is mainly used in the following aspects:

Aerospace

Inconel 718 is an important material in additive manufacturing, especially in the aerospace industry, and is commonly used to produce high-performance engine and turbine components.

Energy Industry

In the energy industry, Inconel 718 is used for manufacturing petroleum and chemical equipment, nuclear reactor components, and solar collector components due to its excellent corrosion resistance and high-temperature stability.

Automotive manufacturing

Inconel 718 is also widely used in the automotive manufacturing industry, especially in manufacturing engine components such as exhaust systems and turbochargers.

Other applications

In addition to the fields mentioned above, Inconel 718 has also been applied in medical devices, chemical reactors, and high-temperature stoves, providing key components for equipment in these fields.

High-quality inconel 718 powder supplier

TRUNNANO is a trusted global supplier and manufacturer of chemical materials with over 12 years of experience in ultra-high quality nanomaterials and chemicals. The company has developed several powder materials and chemicals. Provide OEM service. If you are looking for inconel 718 powder, please get in touch with us. You can click on the product to contact us.