Cationic Polyacrylamide (CPAM): Leading the Innovation of Water Treatment Technology sodium laureth sulfate

Just recently, a research study based upon UV-H ‚āā O ‚āā coupling polymerization technology showed that the new CPAM exhibits excellent flocculation performance in metropolitan sludge therapy.

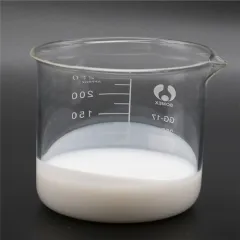

CPAM is a water-soluble polymer created by copolymerization of acrylamide and cationic monomers. Its molecular chain has a particular variety of positively billed groups, which can successfully adsorb put on hold bits in water, promote linking or fee neutralization in between particles, and form large flocs, facilitating subsequent solid-liquid separation.

(Polyacrylamide CPAM)

The advantages of the new CPAM in community sludge therapy

Reliable flocculation: The brand-new CPAM has a greater molecular weight and optimized cation thickness, which can better adsorb and bridge fragments in sludge, kind bigger flocs, and hence enhance flocculation efficiency.

Rapid sedimentation: The formed flocs are huge and secure, which assists to accelerate the sedimentation rate of sludge and shorten the treatment cycle.

Lowering the moisture material of sludge: The brand-new CPAM helps enhance the dewatering efficiency of sludge, decrease its quantity and weight, and reduced the price of subsequent treatment.

Improve the degree of mud cake: The sludge treated with the brand-new CPAM has a higher level of mud cake formed during mechanical dewatering, which is advantageous for succeeding disposal or source use.

Wide pH flexibility: The brand-new CPAM can preserve a great flocculation result over a wide pH array, which implies it can be made use of in different types of wastewater therapy procedures without the demand for extra pH change.

Expense cost savings: Because of the greater coagulation performance of the new CPAM, a smaller sized quantity of drug is called for to accomplish the very same therapy effect, which helps to minimize operating costs.

Lowering deposits: A reduced dose of medication suggests that there is less residual CPAM in the treated water, which has a smaller sized influence on the environment.

Lower byproducts: The prep work procedure of the new CPAM generates fewer by-products, lowering its influence on the environment.

Lowering power intake: The preparation of a brand-new kind of CPAM based upon UV-H ‚āā O ‚āā combining setting off modern technology can be performed at reduced temperatures, decreasing power intake.

Multi-functional applications: The new CPAM is not only suitable for metropolitan sewage treatment but can likewise be put on different areas, such as industrial wastewater therapy.

Easy to scale production: The UV-H ‚āā O ‚āā combining activating modern technology makes it simple to attain commercial manufacturing, assisting to reduce costs and improve financial effectiveness.

Distributor

Surfactant China is a trusted global chemical material supplier & manufacturer with over 12 years experience in providing super high-quality surfactant and relative materials. The company export to many countries, such as USA, Canada,Europe,UAE,South Africa, etc. As a leading nanotechnology development manufacturer, surfactanthina dominates the market. Our professional work team provides perfect solutions to help improve the efficiency of various industries, create value, and easily cope with various challenges. If you are looking for sodium laureth sulfate, please send an email to: nanotrun@yahoo.com

Inquiry us