Silicon Hexaboride Market Report and Outlook (2025-2030) sib 15

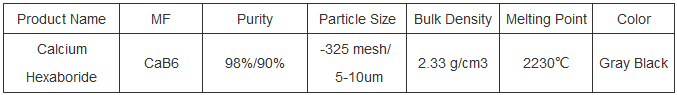

We Offer Silicon Hexaboride Specifications

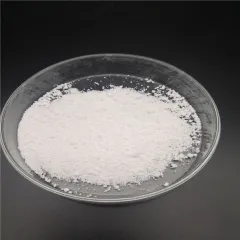

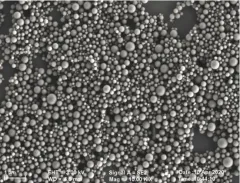

Our Silicon Hexaboride (SiB6) is a glossy black-gray powder defined by its high pureness exceeding 99%. With a relative density of 3.0 g/cm3 and a melting point of 2200 ° C, it makes certain phenomenal performance in high-temperature applications. The bit dimension varies in between 20-40 micrometers, making it appropriate for numerous industrial usages needing accuracy and harmony. Get in touch with us for comprehensive specs and inquiries concerning our Silicon Hexaboride.

(TRUNNANO Silicon Hexaboride)

Introduction

The global Silicon Hexaboride (SiB6) market is poised for considerable growth from 2025 to 2030. SiB6 is a substance with impressive residential or commercial properties, consisting of high solidity, thermal stability, and chemical inertness. These qualities make it very beneficial in different markets, such as electronics, aerospace, and advanced products. This record gives a comprehensive overview of the present market condition, crucial drivers, difficulties, and future potential customers.

Market Overview

Silicon Hexaboride is primarily utilized in the manufacturing of advanced porcelains, abrasives, and refractory materials. Its high hardness and put on resistance make it ideal for applications in cutting tools, grinding wheels, and wear-resistant coatings. In the electronic devices industry, SiB6 is made use of in the fabrication of semiconductor gadgets and as a safety finishing due to its outstanding thermal and chemical security. The marketplace is segmented by type, application, and area, each adding to the overall market characteristics.

Secret Drivers

One of the key motorists of the SiB6 market is the increasing demand for sophisticated ceramics in the aerospace and vehicle industries. SiB6’s high solidity and put on resistance make it a recommended material for making parts that run under extreme problems. In addition, the growing use of SiB6 in the manufacturing of abrasives and refractory materials is driving market development. The electronic devices market’s demand for products with high thermal and chemical security is one more significant driver.

Difficulties

In spite of its many advantages, the SiB6 market encounters numerous obstacles. One of the major difficulties is the high price of production, which can limit its prevalent fostering in cost-sensitive applications. The complicated production procedure, consisting of synthesis and sintering, requires substantial capital investment and technical experience. Environmental problems connected to the removal and handling of silicon and boron are likewise important factors to consider. Ensuring sustainable and eco-friendly production methods is essential for the long-term development of the marketplace.

Technical Advancements

Technical developments play a crucial function in the growth of the SiB6 market. Technologies in synthesis techniques, such as hot pressing and trigger plasma sintering (SPS), have enhanced the top quality and uniformity of SiB6 items. These strategies permit specific control over the microstructure and homes of SiB6, allowing its usage in more requiring applications. Research and development efforts are additionally focused on creating composite materials that incorporate SiB6 with other materials to enhance their performance and expand their application range.

Regional Analysis

The global SiB6 market is geographically varied, with North America, Europe, Asia-Pacific, and the Center East & Africa being vital areas. North America and Europe are expected to maintain a solid market presence as a result of their sophisticated production markets and high demand for high-performance materials. The Asia-Pacific region, particularly China and Japan, is projected to experience substantial growth because of rapid industrialization and increasing financial investments in r & d. The Center East and Africa, while currently smaller sized markets, show potential for development driven by framework growth and arising sectors.

Competitive Landscape

The SiB6 market is very competitive, with numerous well established gamers controling the market. Key players consist of companies such as H.C. Starck, Alfa Aesar, and Advanced Ceramics Corporation. These firms are continuously purchasing R&D to create cutting-edge products and broaden their market share. Strategic collaborations, mergings, and procurements are common approaches employed by these firms to remain ahead in the market. New entrants deal with challenges due to the high first financial investment required and the need for sophisticated technical abilities.

( TRUNNANO Silicon Hexaboride )

Future Prospects

The future of the SiB6 market looks appealing, with numerous elements anticipated to drive development over the following 5 years. The boosting concentrate on sustainable and reliable production processes will certainly produce brand-new opportunities for SiB6 in numerous industries. Additionally, the advancement of new applications, such as in additive production and biomedical implants, is anticipated to open brand-new opportunities for market expansion. Federal governments and personal organizations are likewise purchasing study to discover the complete potential of SiB6, which will certainly further add to market development.

Final thought

Finally, the worldwide Silicon Hexaboride market is readied to expand substantially from 2025 to 2030, driven by its special buildings and broadening applications throughout several sectors. Regardless of encountering some obstacles, the market is well-positioned for long-term success, supported by technical developments and tactical campaigns from principals. As the demand for high-performance products remains to climb, the SiB6 market is expected to play a crucial function in shaping the future of production and modern technology.

TRUNNANO is a supplier of Silicon Hexaboride with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you want to know more about sib 15, please feel free to contact us and send an inquiry(sales5@nanotrun.com).

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us