The Backbone of Durability and Color: Uncovering the Multifaceted Applications and Future Potential of Chromium Oxide chromium download for windows 10

Intro to Chromium Oxide

Chromium oxide (Cr two O TWO) stands apart as an impressive compound, crucial in many industrial applications as a result of its outstanding properties. From boosting the durability of products to providing dynamic environment-friendly pigments, chromium oxide plays an important role in modern market. This write-up delves into the distinct attributes, prevalent applications, and future capacity of chromium oxide.

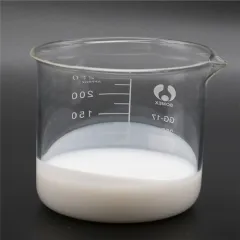

(TRUNNANO Cr2O3 Powder)

Composition and Production Process

Chromium oxide is made up of chromium and oxygen atoms set up in a crystalline structure that provides it amazing stability and solidity.

The production of Cr ₂ O two involves oxidizing metal chromium at high temperatures. This process guarantees purity and uniformity, making it ideal for a variety of applications. Its resistance to deterioration and abrasion makes it suitable for usage in finishes, ceramics, and refractory materials. The capability to withstand severe conditions without destruction underpins its value throughout numerous sectors.

Applications Across Various Sectors

Chromium oxide discovers considerable use across several fields as a result of its diverse residential or commercial properties. In the metallurgical market, it acts as a vital element in the manufacturing of stainless steel and various other alloys, boosting their resistance to put on and deterioration. As a pigment, chromium oxide gives a deep green color utilized in paints, plastics, and inks. Additionally, its application in unpleasant materials like grinding wheels and brightening substances boosts efficiency and complete top quality. Each industry benefits from the effectiveness and flexibility of chromium oxide.

Market Fads and Growth Drivers

The need for chromium oxide is on the rise, driven by expanding end-user markets such as building and construction, automobile, and electronic devices. Developments in manufacturing processes boost top quality and minimize prices, making sure regular performance. Strenuous testing confirms product efficiency, causing remarkable products. Firms embracing these modern technologies supply enhanced offerings. Consumer understanding concerning the benefits of chromium oxide, such as boosted item durability and visual allure, drives market interest. Marketing initiatives educate consumers on the benefits of items including chromium oxide.

Difficulties and Limitations

One substantial obstacle associated with chromium oxide is ecological issue over hexavalent chromium exhausts throughout production and usage. This form of chromium can present wellness risks otherwise properly taken care of. An additional problem is price volatility because of varying raw material prices. Nonetheless, continuous research seeks lasting options and techniques to minimize ecological impacts. Clear interaction concerning sustainability campaigns constructs count on amongst consumers and regulatory authorities. Initiatives to minimize ecological impact are vital for the continued viability of chromium oxide.

Future Leads: Developments and Opportunities

The future looks promising for chromium oxide with continual research aimed at enhancing its residential or commercial properties while attending to environmental worries. Innovations consist of establishing greener production approaches and checking out new applications in emerging innovations. As industries go after more long lasting and sustainable options, chromium oxide will certainly stay important. Its reliability and adaptability ensure its worth in various applications, from durable goods to industrial processes. New developments might unlock added uses, driving more growth and development.

End of Record

( TRUNNANO Cr2O3 Powder)

This version presents a thorough yet easily accessible exploration of chromium oxide, highlighting its value and possible across different fields. By concentrating on practical applications and future chances, the post aims to provide readers with a detailed understanding of this functional compound. The title and web content are developed to involve specialists and lovers alike, emphasizing both depth and relevance.

Provider

TRUNNANO is a supplier of Chromium Oxide with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you want to know more about Chromium Oxide, please feel free to contact us and send an inquiry(sales5@nanotrun.com).

Tags: chromium oxide, chromium trioxide, chromium iii oxide

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us