The Unsung Hero of Advanced Materials: Unveiling the Power of Aluminum Nitride aluminum nitride ceramic

Introduction to Light Weight Aluminum Nitride

Light weight aluminum nitride is a remarkable product. It has distinct residential properties that make it valuable in several fields. This product can hold up against heats and is an outstanding conductor of warm. These features make it perfect for electronics, illumination, and much more. This short article discovers what makes aluminum nitride unique and just how it is utilized today.

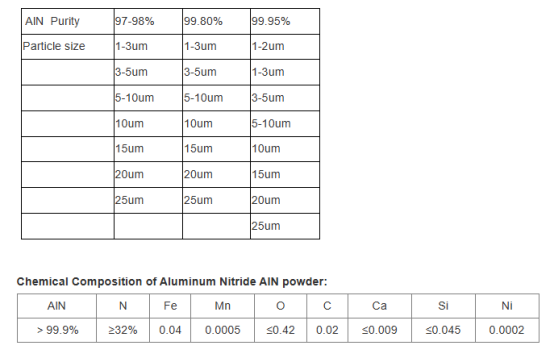

(TRUNNANO Aluminum Nitride Powder)

Make-up and Manufacturing Process

Aluminum nitride is made from light weight aluminum and nitrogen. These components are integrated under controlled problems to create a strong bond.

To make aluminum nitride, pure aluminum is heated with nitrogen gas. The response creates a powder. This powder is then pressed right into forms or sintered to produce solid pieces. Unique procedures can readjust the purity and residential or commercial properties of the final product. The result is a versatile product ready for use in different applications.

Applications Throughout Various Sectors

Electronic devices Industry

In electronics, light weight aluminum nitride is utilized in semiconductors and circuits. It conducts heat well, which aids trendy devices. This prevents overheating and expands the life of electronic parts. Aluminum nitride is likewise used in power components and LED lighting. Its ability to deal with high temperatures makes it a reliable option.

Aerospace and Defense

Aerospace designers value light weight aluminum nitride for its stamina and thermal conductivity. It is used in sensors and actuators that need to operate in severe problems. Airplane and spacecraft utilize these elements to keep an eye on and manage systems. Aluminum nitride aids ensure these systems work dependably also in severe atmospheres.

Medical Devices

Medical devices gain from aluminum nitride as well. It is used in imaging equipment and analysis tools. Aluminum nitride’s capability to perform warm efficiently assists boost the performance of these gadgets. It also withstands deterioration, making it risk-free for use in clinical setups. Medical facilities and centers depend on this material for accurate diagnostics.

Automotive Field

The vehicle sector uses light weight aluminum nitride in electrical lorries. It assists manage heat in batteries and power electronic devices. Reliable warm dissipation is crucial for the performance and safety and security of electrical automobiles. Light weight aluminum nitride makes sure these systems remain amazing and operate smoothly. This contributes to the overall performance of electric cars.

( Aluminum Nitride Powder)

Market Patterns and Growth Motorists: A Positive Viewpoint

Technical Advancements

New modern technologies boost how light weight aluminum nitride is made. Better producing approaches lower expenses and increase high quality. Advanced testing lets manufacturers examine if the materials function as expected. This assists develop better products. Firms that take on these innovations can offer higher-quality light weight aluminum nitride.

Increasing Need in Electronics

The demand for aluminum nitride expands as electronics end up being more advanced. Extra devices need efficient air conditioning remedies. Aluminum nitride offers a method to maintain devices going for ideal temperature levels. As innovation evolves, the use of aluminum nitride will likely boost.

Customer Recognition

Consumers currently recognize much more concerning the advantages of aluminum nitride. They search for products that use it. Brand names that highlight using aluminum nitride bring in more consumers. People count on items that execute far better and last much longer. This pattern increases the market for aluminum nitride.

Difficulties and Limitations: Navigating the Path Forward

Expense Issues

One difficulty is the cost of making aluminum nitride. The procedure can be pricey. Nonetheless, the benefits commonly exceed the prices. Products made with light weight aluminum nitride last much longer and perform far better. Business should reveal the value of aluminum nitride to warrant the cost. Education and learning and marketing can aid.

Safety Problems

Some stress over the safety and security of aluminum nitride. It has aluminum, which can pose threats otherwise managed appropriately. Research study is continuous to make certain aluminum nitride is safe. Rules and standards help control its usage. Business should adhere to these policies to secure consumers. Clear interaction about safety can develop trust fund.

Future Potential Customers: Advancements and Opportunities

The future of light weight aluminum nitride looks promising. A lot more research will certainly find new methods to utilize it. Developments in materials and modern technology will certainly boost its efficiency. As sectors seek much better services, aluminum nitride will certainly play a crucial duty. Its capability to carry out warmth and withstand heats makes it useful. The constant development of aluminum nitride promises interesting possibilities for growth.

High-quality Aluminum Nitride Provider

TRUNNANO is a supplier of boron nitride with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you want to know more about aluminum nitride ceramic, please feel free to contact us and send an inquiry(sales5@nanotrun.com).

Tags: aluminum nitride,al nitride,aln aluminium nitride

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us