Wastewater resource usage is the future advancement instructions of sewer treatment and is also an inescapable need for lasting human growth. Raw material drawn out from sewage or sludge, such as minerals and phospholipids, can be used as printing and coloring resources, key adsorbents, and biological flocculants. It is used in water therapy, agriculture, gardening, the paper industry, medical care, the building and construction market, and other areas and has great relevance. Recycling worth.

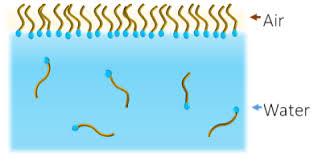

(surfactant)

There are many types of bacteria in the continuing to be sludge. For that reason, the compounds drawn out from it needs to be a combination of various polymer compounds. Whether they are intracellular or extracellular polymer materials, they all have normal energetic teams, such as carboxyl, hydroxyl, and phosphate. Teams and various other functional teams. The existence of these teams permits the extracted polymer materials to be utilized as hefty metal ion adsorbents.

As a clean therapy modern technology, ultrasonic waves do not call for the enhancement of chemicals throughout the activity and will not create secondary contamination. Ultrasonic waves can disperse flocs in the water phase, and the cavitation result can break big bits into little bits. Ultrasound is an energy-intensive treatment approach, and its largest disadvantage is its high energy consumption, which restricts the possibility of sensible applications. Surfactant has a solubilizing effect, which can clean off healthy proteins on the cell membrane layer, increase the permeability of the cell membrane by impacting the osmotic pressure, and magnify the damages to the sludge floc. Furthermore, surfactant activity can promote the extraction of EPS from staying sludge, transform the cell framework, and impact sludge properties.

Surfactant-enhanced ultrasonic techniques can be utilized to draw out natural polymer products and as a pretreatment approach to decrease energy usage. The increase in the extraction quantity of PSs from the continuing to be sludge under the activity of surfactant-enhanced ultrasound is because of the launch of raw material due to floc disintegration and cell dissolution.

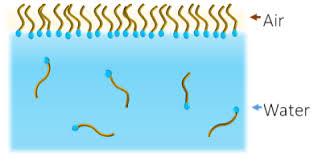

(surfactant)

First, surfactants, such as anionic (such as salt dodecyl sulfate, SDS) and cationic (such as cetyltrimethylammonium bromide, CTAB), are made use of to enhance the partnership between sludge and polymer compounds. Interactions in between. They can reduce the surface area tension of sludge, making it less complicated for polymer materials to divide from sludge.

Subsequently, ultrasound is presented to boost the removal effect further. The solid resonance and shock waves produced by ultrasonic waves can destroy the framework of sludge and tear cell walls, thereby releasing more polymer substances. Additionally, ultrasound can likewise promote the communication between surfactants and polymer compounds, making the removal procedure more efficient.

During the extraction process, it is additionally essential to maximize the experimental specifications, such as the frequency, power, and action time of ultrasonic waves, to attain the most effective extraction effect.

(surfactant)

Generally, surfactant-enhanced ultrasonic removal of polymer substances in recurring sludge is an effective and ingenious technique. It not only improves removal performance yet likewise helps increase the extent of source use of remaining sludge, offering new opportunities for the development of sewage therapy and source healing fields. However, the practical application of this approach needs more research study and optimization to address feasible technical difficulties and economic issues.

Supplier

Surfactantchina is a trusted global chemical material supplier & manufacturer with over 12 years experience in providing super high-quality surfactant and relative materials. The company export to many countries, such as USA, Canada,Europe,UAE,South Africa, etc. As a leading nanotechnology development manufacturer, surfactanthina dominates the market. Our professional work team provides perfect solutions to help improve the efficiency of various industries, create value, and easily cope with various challenges. If you are looking for sodium laureth sulfate, please send an email to: nanotrun@yahoo.com

Inquiry us